BayaTronics was founded to help companies create affordable, quality products here in the US.

Our mission is to be the leading provider of high-quality printed circuit board assemblies, delivering precision-engineered solutions that power the innovations of tomorrow.

Founded in 2021, BayaTronics is an electronic manufacturing service provider located in Concord, North Carolina.

Management team has 40+ years of experience in PCBA and electro-mechanical sub-assemblies at Tier1 contract manufacturers and OEMs in Industrial & Medical fields.

The management team actively participated in the Malcolm Baldrige National Quality Award competition winning the award twice. The lessons learned during this time initiated the desire to create BayaTronics in the future.

It is the goal of BayaTronics to provide domestic customers with a high volume, cost competitive solution with superior quality. Time to market is also a major focus for our customer’s innovative products. We intend to establish an open partnership with our customers.

Why BayaTronics?

- Founded in 2021, Current CEO is Dirk Warriner (41 years of experience)

- Full team to support all our customers' needs providing flexibility for each customer

- 200% revenue growth from 2022 to 2023

- Located in Concord, North Carolina

Responsive Support

We offer day-of responses to customer emails, texts, and calls, ensuring quick support. Quotes are provided within five working days, and our manufacturing cycle time is designed to meet customer needs efficiently.

Integrity Standards

We ensure full transparency in cost and quality, uphold honest business dealings, and prioritize clear communication.

Final Assembly

Our Final Assembly services deliver precision in mechanical assembly, comprehensive testing, and flawless product performance. Backed by years of industry expertise, we ensure every product meets the highest standards.

Quality Assurance

Our team brings 208 years of experience, ensuring quality, meticulous attention to detail, and reliable product performance.

Difference with Our Solutions

We uphold the highest quality standards in every aspect of our manufacturing process, from design to delivery, ensuring that our products consistently exceed customer expectations. Through continuous improvement, cutting-edge technology, and a dedicated team, we strive to support our customers in creating reliable, efficient, and impactful electronic products that drive progress in a rapidly evolving world.

Industry best practices

We have carried out numerous successful implementations in advanced fields of science, such as cell therapy, gene therapy, and antibodies.

Pre-built solution templates

The Customer Experience team has created solution templates that are readily available and can be quickly transferred to a production-ready environment, resulting in time savings, cost reduction.

End-to-end workflows

Inventory management is vital for ensuring that all required materials and resources are available when needed throughout the R&D process.

End-to-end workflows

Inventory management is vital for ensuring that all required materials and resources are available when needed throughout the R&D process.

"Through continuous improvement, cutting-edge technology, and a dedicated team, we strive to support our customers in creating reliable, efficient, and impactful electronic products that drive progress in a rapidly evolving world."

Dirk Warriner, CEO BayaTronics

Intelligent Storage System

Juki ISM3600

- 1912 reels 7″ 8mm + 445 reels 15″ 8mm

- Humidity controlled

- ESD compliant

Juki ISM500

- Fits PCBs, SMT trays, SMT tubes

- 640 configurable positions

- Humidity controlled

- 3 LEDs per position

- ESD compliant

- Add Cut Tape bags

- 2 Step verification upon extraction

Solder Paste Printer

Juki G-Titan

- Auto paste dispensing

- Flexible clamping (side or top)

- 2D PCB and stencil aperture inspection

- Solder paste rolling measurement

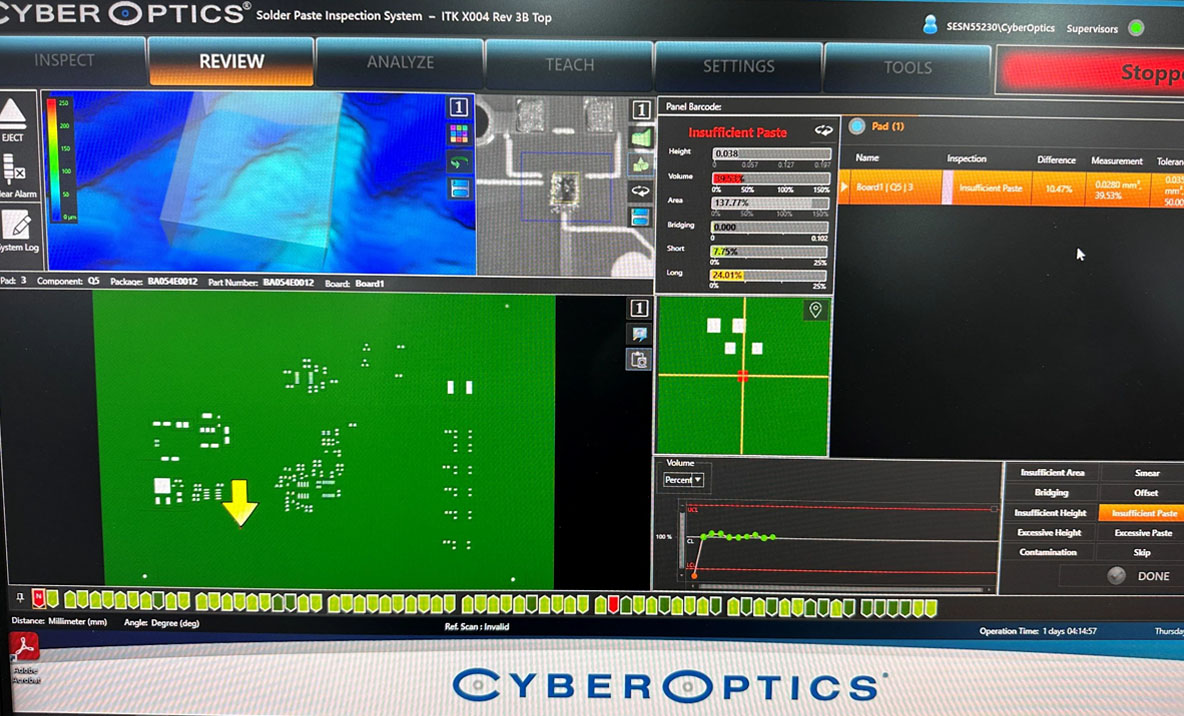

Solder Paste Inspection

Cyber Optics SE500 Ultra

Features:

- Max length 20 inches by 19.8 inches

- Paste height range 2-20 mils

- Inspection speed 210 cm² per second

Insuffficent solder

Surface Mounters

Juki RS-1R

- Two in-line mounters

- 224 feeder inputs

- Optimum placement speed: 47,000 CPH

- Placement accuracy ±35um (CPK >=1)

- 20 x 14.5in max PCB dimensions

- 8 nozzle adaptive placement heads

- Matrix tray changer supports 30 trays

Reflow Ovens

Juki

- 8 Zones + 2 Zones

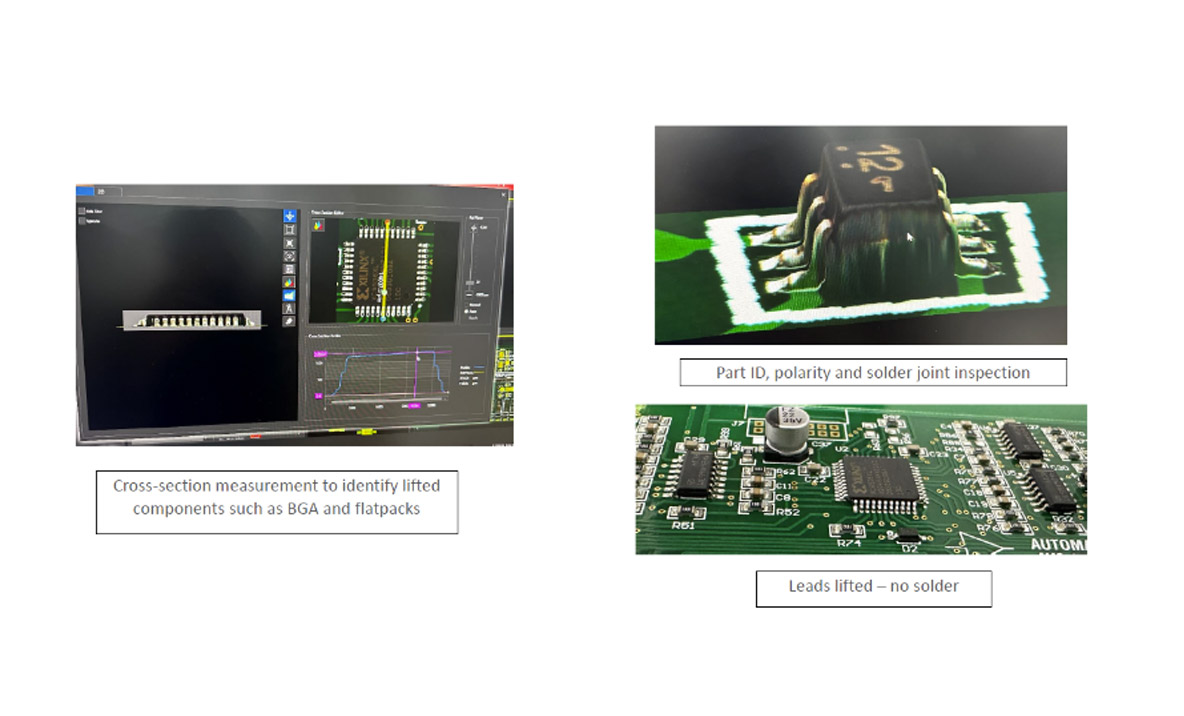

Solder Paste Inspection

Cyber Optics SQ3000

- Max length 20 inches by 20 inches

- Inspection speed 20cm squared per second

- Component defects: missing, polarity, tombstone, flipped, wrong part, lead damage

- Solder joint defects: excess, insufficient, bridging

- 3d inspection: lifted lead, coplanarity, polarity dimple

Selective Soldering System

Juki iCUBE

- Dual nozzle (assorted sizes)

- Inline

- Up to 20x18in PCB input

- Pb-free solder pots

- Microdrop fluxer (less cleaning)

- N2 pre-heater

- 2 or 4 zone pre-heater for PCB

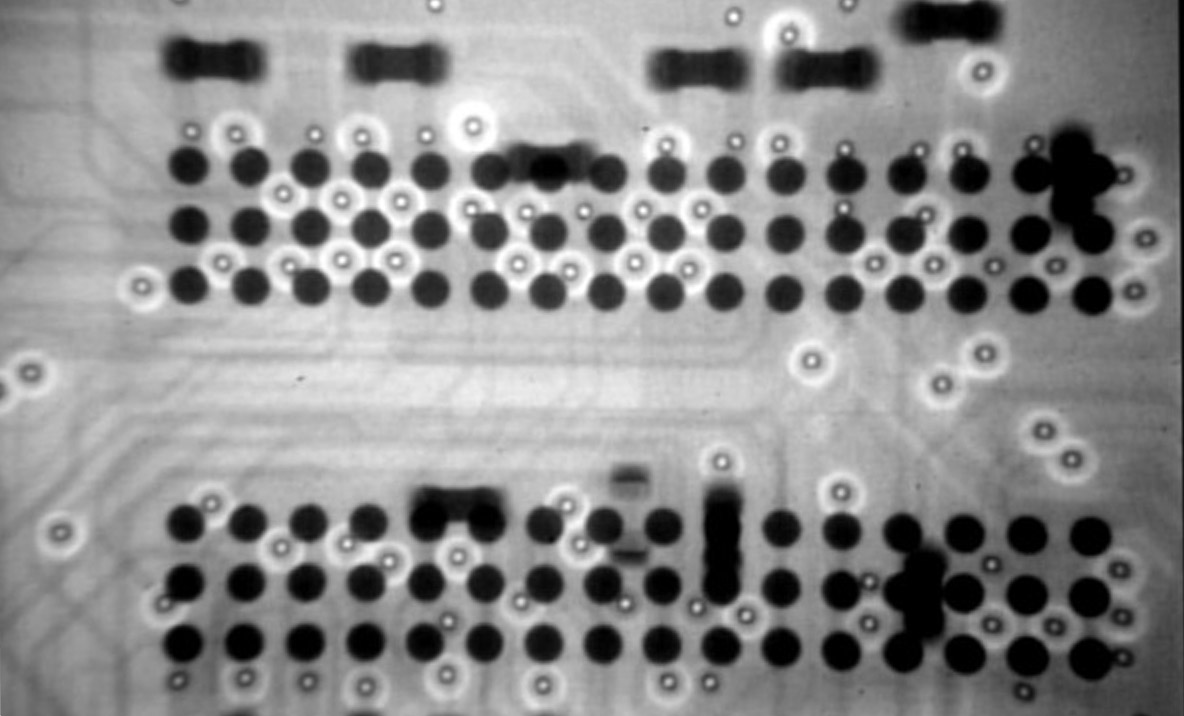

X-Ray

Flying Probe Testing

Seica Pilot V8 Next Series

- FNODE signature analysis on the nets of the UUT

- Standard analog and digital in-circuit test

- Vectorless tests (AUTIC and OPENFIX), to test ICs for opens and shorts

- PWMON digital net analysis

- Continuity test to detect open tracks on the PCB

- Visual tests for component presence/absence and rotation

- On Board Programming tools for digital devices

- ALI: Automatic Laser Inspection for presence/absence and warpage compensation

- LED Sensor for light intensity