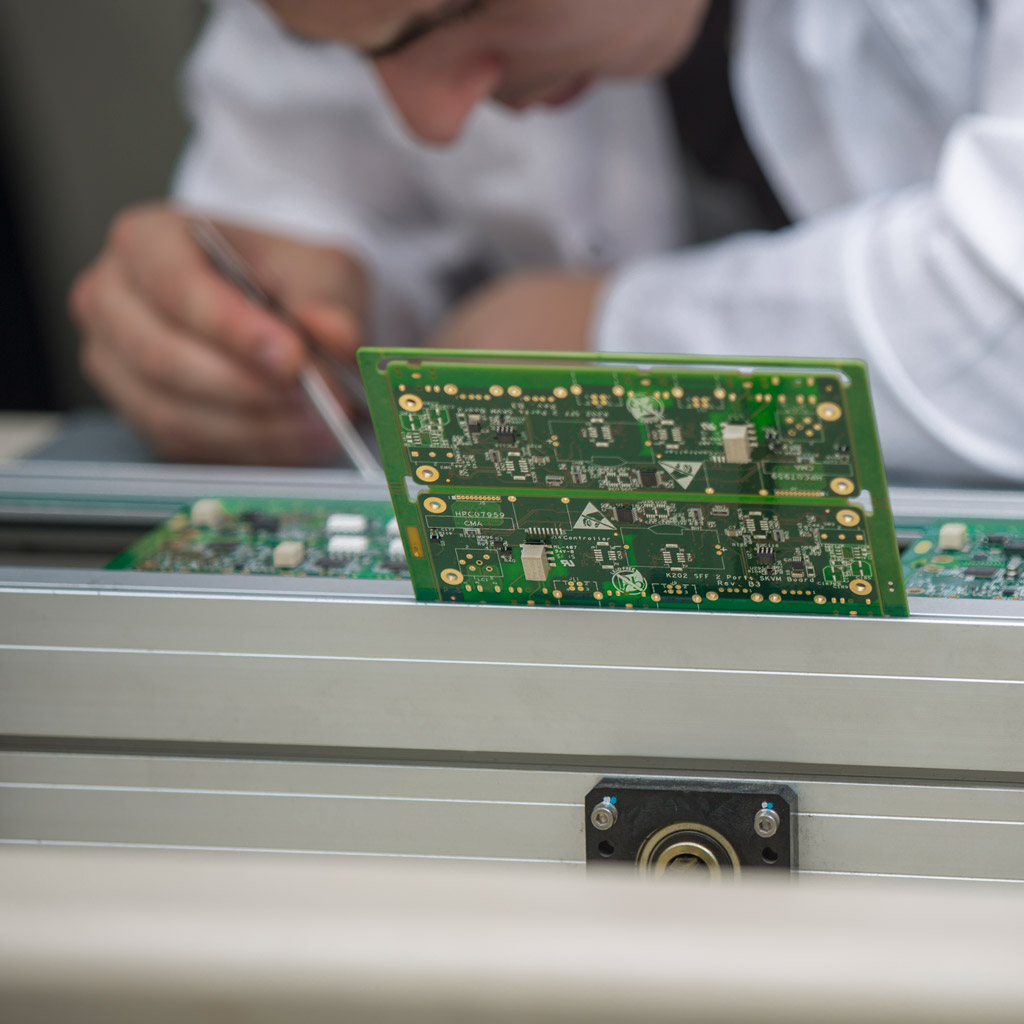

BayaTronics provides high-quality solutions and careful project handling

We uphold the highest quality standards in every aspect of our manufacturing process, from design to delivery, ensuring that our products consistently exceed customer expectations.

Our advanced manufacturing services

Design and production volume determines material cost, which has a major impact on the overall cost of a product. We will encourage and assist our customers with design for manufacturability, new product introduction, and the procurement of materials without burdening the customer with excess material cost. Our partnership with customers begins with involvement in the design concept, continues with new product introduction, and commitment to achieve volume production with required capacity.

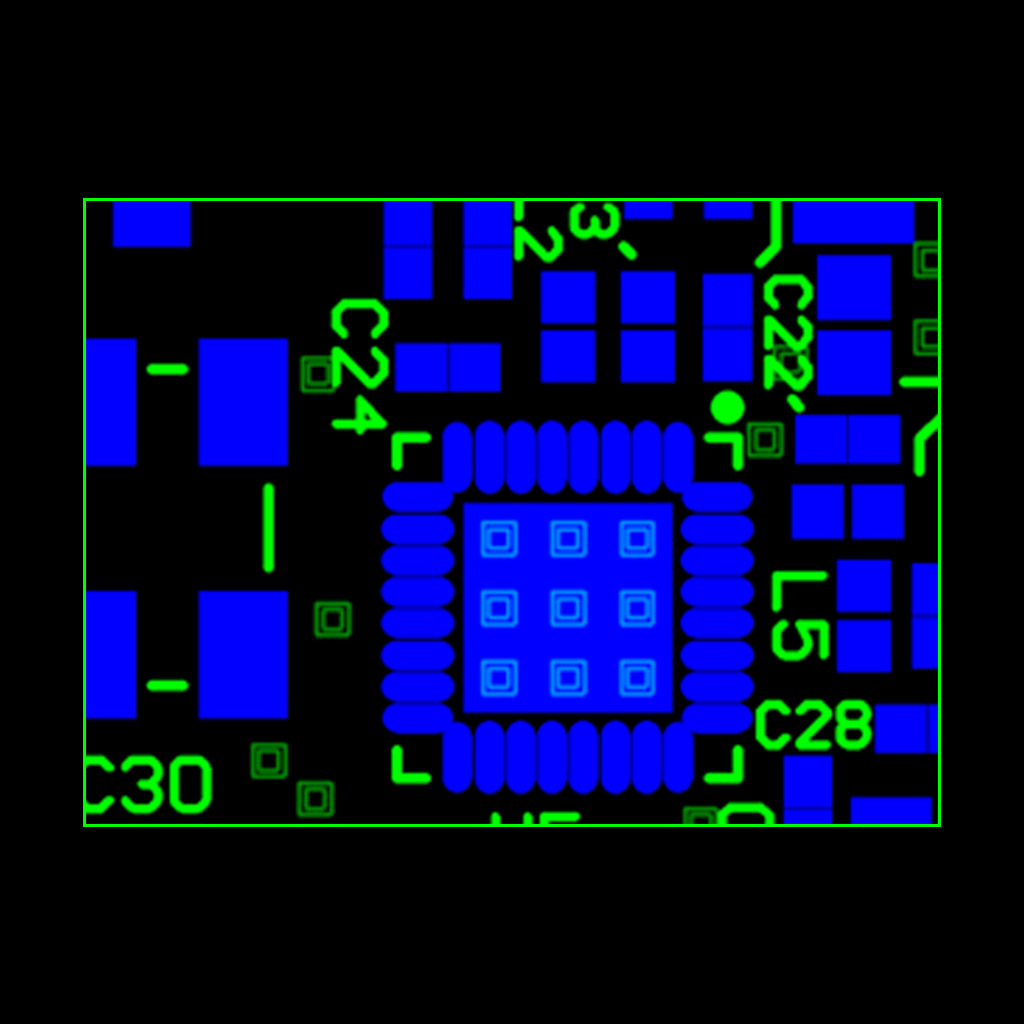

Printed Circuit Board Assembly (PCBa)

At BayaTronics, we specialize in Printed Circuit Board Assembly, leveraging our state-of-the-art Juki equipment. Our advanced inspection techniques, including:

- Solder Paste Inspection (SPI), Automated Optical Inspection (AOI), X-Ray inspection, Flying Probe, and In-Circuit testing ensure precision and reliability.

- Collaborate with diverse data formats including experimental data, operating protocols, and observations.

- Reduce potential hazards and offer data governance tools to regulate accessibility and ensure adherence to regulations.

DFM (Design for Manufacturability)

BayaTronics is dedicated to being more than just a manufacturer—we are your partner in innovation. We engage with our customers from the very beginning of the design process, providing expertise in:

- DFM optimization ensures products are efficient for cost-effective production.

- We support new product introduction, helping bring designs to life.

- We minimize costs while maintaining high standards of quality and reliability.

Final Assembly

Our Final Assembly services at BayaTronics are tailored to bring your products to completion with precision and care.

- We handle mechanical assembly per customer documentation, ensuring precise component fitting and securing.

- We conduct thorough functional tests using customer-supplied equipment or custom in-house fixturing.

- With 208 years of combined experience, we guarantee every product is ready to perform flawlessly.

Logistics

BayaTronics takes pride in managing the complex logistics that come with modern electronics manufacturing. Our dedicated Material Management team oversees the entire supply chain, ensuring that every component is where it needs to be, when it needs to be there.

- We utilize a humidity-controlled storage system for active and passive components to ensure optimal preservation.

- Our MRP system supports rigorous inventory control for both in-process and stored materials.

- With a global procurement footprint, we provide the best materials at competitive prices, ensuring full transparency and clear communication with our customers.

From pre-assembly assessments to logistics, we provide complete capabilities to meet your needs.

01

Pre-Assembly

- DFM Assessments

- Turn-Key Open Book Pricing

- Material Management

02

Assembly

- SMT/PTH

- In-Line AOI & SPI

- Conformal Coating

- Electromechanical Assembly

03

Post-Assembly

- Test

- Failure Analysis

- Repair/ECO

- Logistics

- Order Fulfillment